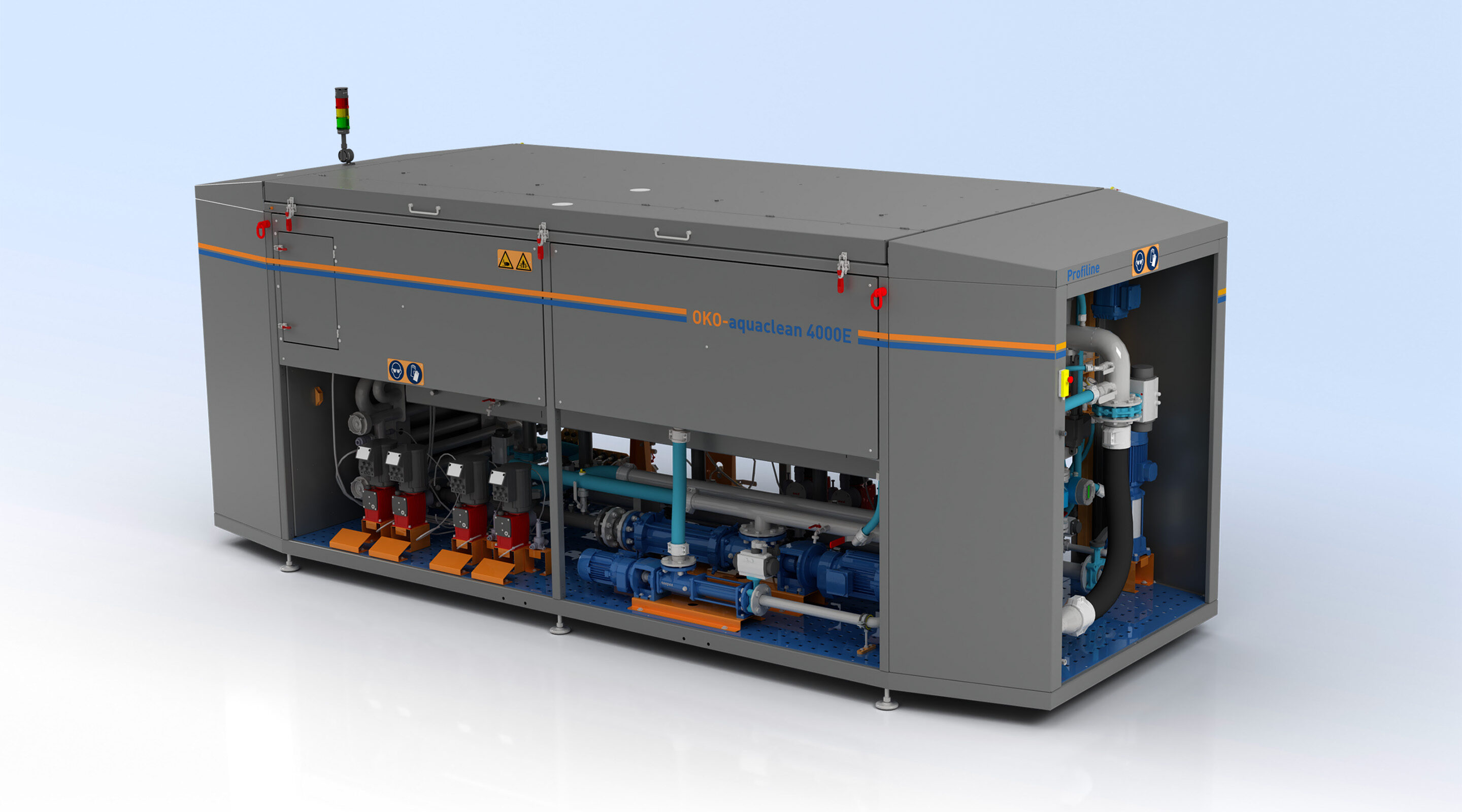

Stable emulsions, such as used cooling lubricants, landfill leachate, process waters containing heavy metals and degreasing baths containing emulsifiers, are treated physico-chemically. The OKO-aquaclean system can efficiently break stable emulsions by using modern and highly effective demulsifiers; it can also remove heavy metals from wastewater.

Benefits

Flotation (DAF)

In flotation, wastewater constituents are removed from the water by adding air. OKO-tech’s high-performance flotation is a process integrated into the system that floats and separates the smallest particles or oil droplets by generating microscopically small air bubbles. The reactor with 7 chambers and a flow-optimised flotation module (ODAF) is equipped with an automatic level-control system for the volume flow selected (OVR).

Pump Technology

The wastewater to be treated is pumped into the OKO-aquaclean system with a low-pulsation progressive cavity pump. As an alternative to discharge by gravity, the treated wastewater can also be pumped over greater distances or into higher tanks using an integrated clear water pump. The separated wastewater components accumulate in the skimmed flotation froth, which is pumped to a collection tank or a dewatering unit by an optional froth pump.

Dosing Technology

Depending on the treatment task, the OKO-aquaclean system can be equipped with up to 9 dosing pumps. Usually, one to four dosing pumps are installed depending on the defined treatment process. The dosing capacity of the pumps is calibrated to the respective medium to be pumped, thus ensuring exact dosing, and avoiding unnecessary costs due to overdosing.