Sludge from oil-water separators tends to form capillaries more intensively than sludge from sewer cleaning, for example, due to surfactants and MOH as well the high proportion of fine silt (95% of the grains are smaller than 63 µm) in the sludge. Water is bound in the microscopically small capillaries like in a sponge, making dewatering considerably more difficult. One possible option is the use of pressure for dewatering the sludge – in a chamber filter press, for example. OKO-ewcs 7 presents a much more economical option: capillaries are destroyed by vibration, thus achieving a good degree of dewatering.

Benefits

Function Description

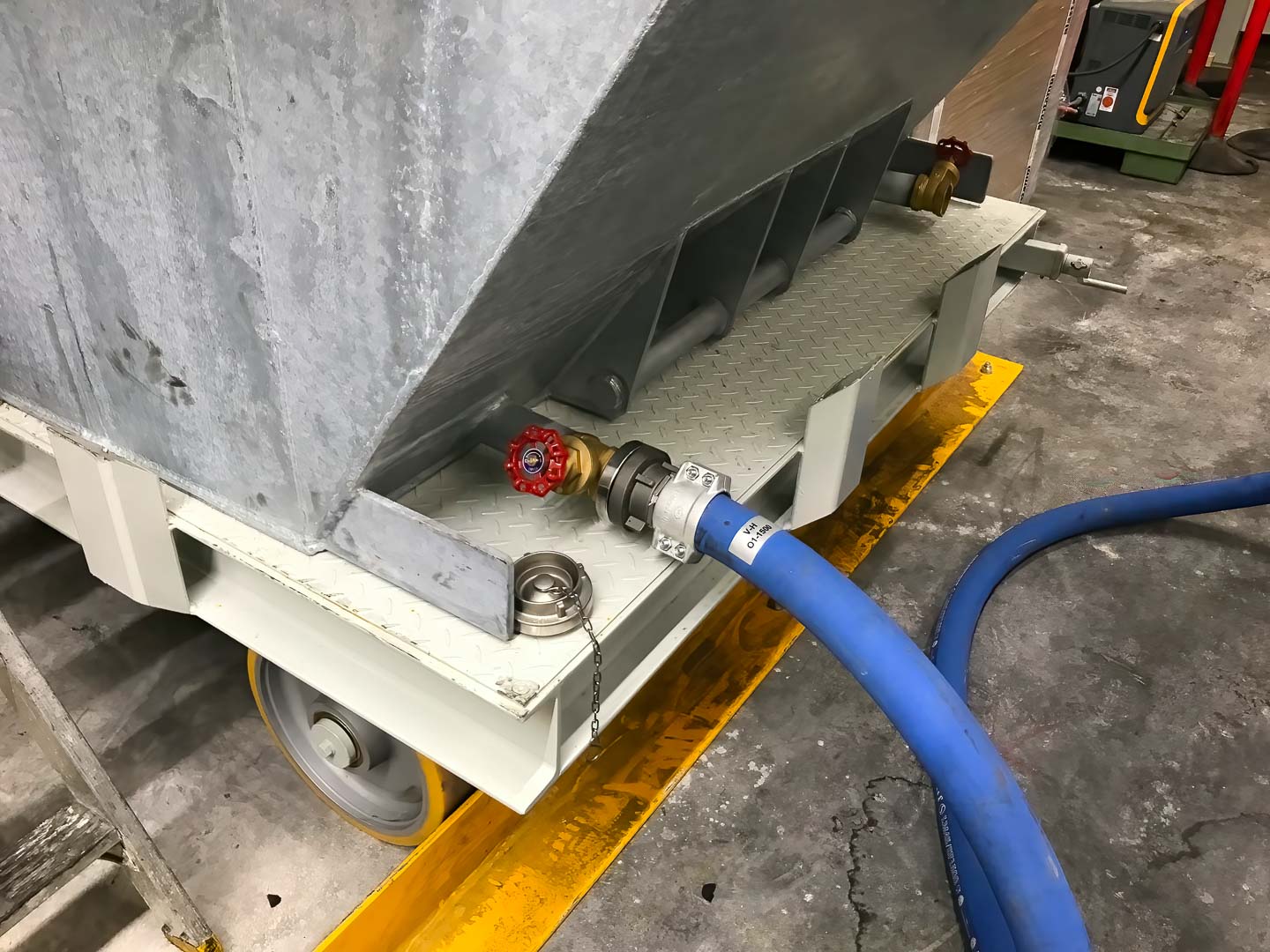

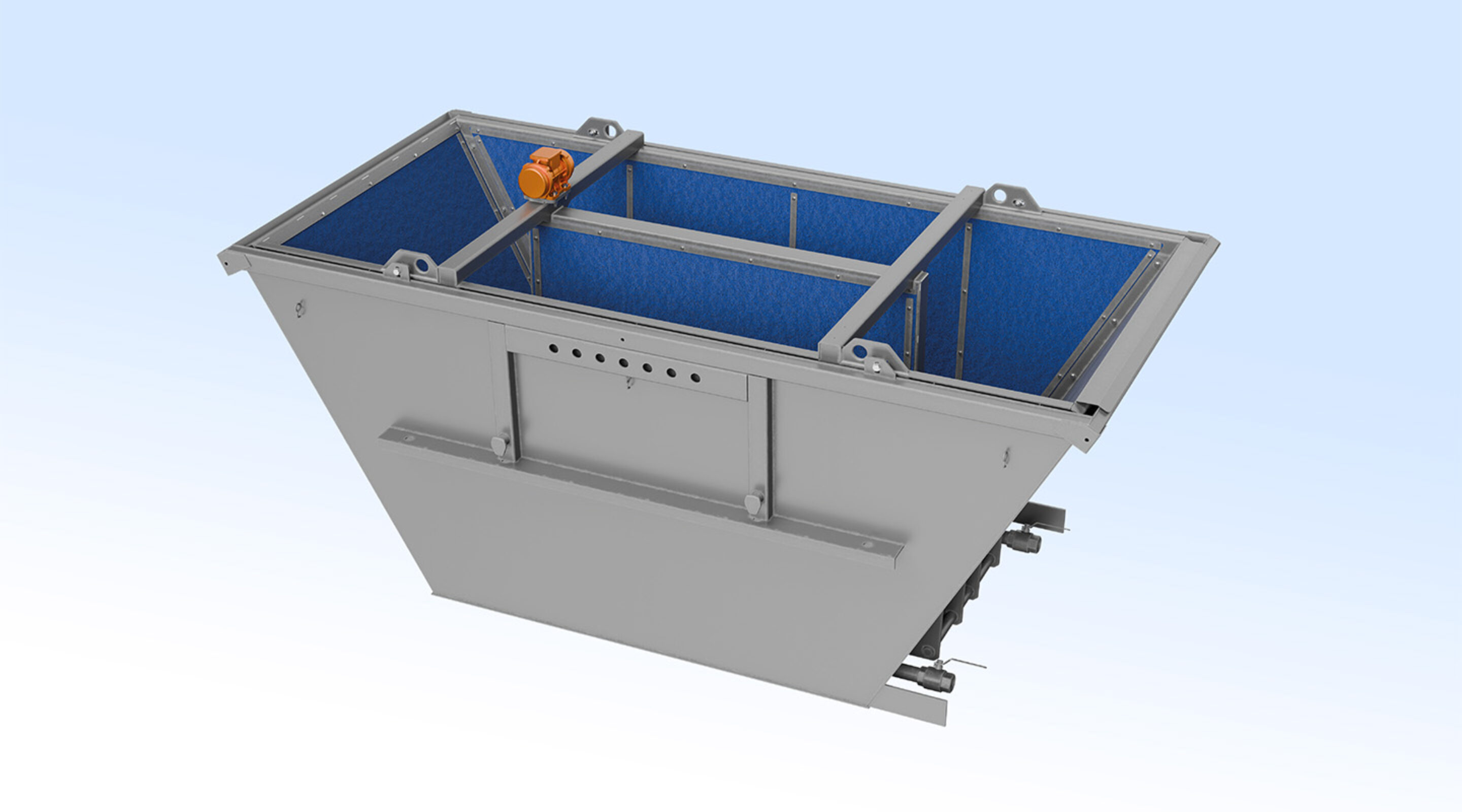

The OKO-ewcs 7 dewatering container consists of a standardised skip loader system in accordance with DIN 30720 featuring a built-in, float-mounted screen basket. The screen basket walls, and the centre dewatering bar are covered with a filter fleece, through which the filtered water enters the cavity between the container and the support for the screen basket. From here, the water is drained via ball valves for further treatment. The design of the inner filter basket as a vibrating/oscillating screen significantly increases sludge dewatering and drying, compared to a static screen basket. The container is emptied by tilting.